In the world of manufacturing, consistency and precision are critical for long-term success. Without reliable tooling, even the best designs can fail. That is why injection mold tooling by Allwell Cast delivers reliable results every time. Known for quality engineering and attention to detail, Allwell Cast has earned trust across industries.

Using advanced processes and a skilled workforce, Allwell Cast creates mold tooling systems that meet strict performance and durability standards. But what exactly makes these tools dependable? Let’s explore the elements that help Allwell Cast maintain consistent success in this competitive space.

Expertise in Precision Tool Design and Engineering

Precision is the foundation of any successful injection mold tooling project. At Allwell Cast, every tool starts with a detailed engineering plan. Skilled designers use advanced CAD software to model every aspect of the mold before production begins.

This careful planning stage allows potential issues to be resolved early in the process. Once the design is finalized, high-tolerance machining ensures that every detail is accurately translated into the final tool. The result is a mold that performs consistently, even under demanding production conditions.

Additionally, the team at Allwell Cast includes engineers with decades of tooling experience. Their expertise helps identify and prevent design flaws that could impact cycle times or part quality.

High-Quality Materials for Long-Term Durability

To produce reliable tools, the materials must be strong and heat-resistant. Allwell Cast sources premium-grade metals that can withstand high-pressure injection processes without deforming. The choice of material depends on the application, but the company always selects options based on durability and wear resistance.

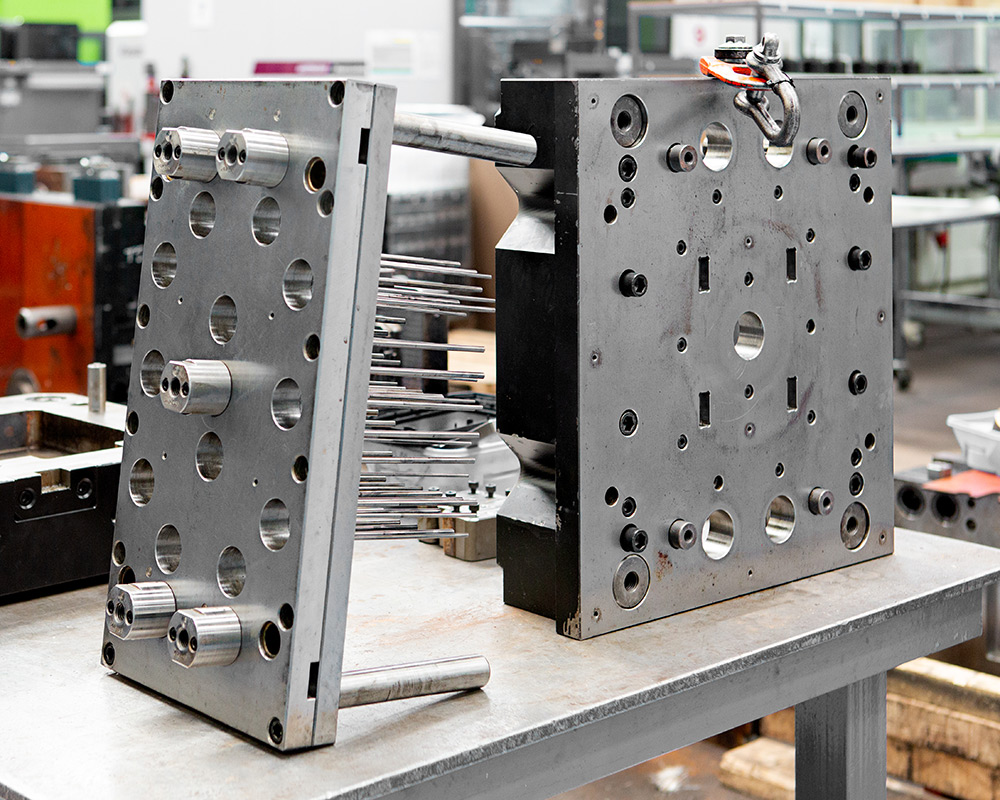

Tool steel is often used for core and cavity inserts, while hardened alloys may be applied to moving parts. Because these tools are expected to run thousands of cycles, durability is essential. Even with repeated use, the injection mold tooling by Allwell Cast remains stable and precise.

Moreover, surface treatments such as polishing and coating are added to extend tool life further. These finishing touches improve ejection, reduce sticking, and protect against corrosion or thermal stress.

Advanced Manufacturing Processes That Ensure Accuracy

Allwell Cast applies advanced CNC machining, EDM technology, and inspection tools to build each mold. These processes are controlled by tight quality systems to reduce human error and guarantee repeatable accuracy. Tooling components are measured at each stage to maintain dimensional consistency.

This emphasis on technology does not eliminate craftsmanship. In fact, highly trained technician’s complete final adjustments manually, ensuring all components fit perfectly. It’s this balance of automation and human skill that helps Allwell Cast achieve excellent results.

Once assembled, molds are tested under real production conditions. Any necessary modifications are completed before the final tool is delivered. This extra layer of validation prevents costly delays for clients.

Consistent Part Quality in High-Volume Production

Manufacturers choose injection mold tooling from Allwell Cast because it ensures consistent part quality over time. Tolerances are maintained from the first part to the last, which reduces waste and minimizes rework. That is especially important for industries like automotive, consumer electronics, and medical devices.

Because the tooling is designed to handle tight tolerances, clients experience fewer defects and more reliable outcomes. The design and build process also considers thermal expansion, cooling efficiency, and gate placement. These details affect how the plastic flows inside the mold, which directly impacts the final product’s appearance and strength.

Even in high-volume runs, the tooling remains stable and efficient. This helps clients meet production goals without compromising on precision or finish.

Customization Options for Diverse Industry Needs

Not every project fits a standard mold design. That is why Allwell Cast offers customizable tooling solutions to match specific customer requirements. Whether clients need multi-cavity molds, insert molds, or over-molding setups, the engineering team provides tailored designs.

Because many industries rely on unique part geometries or materials, customization plays a huge role. Clients benefit from the flexibility to choose mold features that improve speed, quality, and cost-efficiency. The result is a system that fits seamlessly into existing production lines.

In addition to tool design, Allwell Cast supports clients with design-for-manufacturability (DFM) analysis. This service helps clients improve product design before tooling begins, reducing long-term costs and development timelines.

Comprehensive Support and After-Sales Service

One of the reasons injection mold tooling by Allwell Cast delivers reliable results is the support clients receive throughout the process. From early consultations to post-delivery assistance, the team remains available to solve problems and make adjustments when needed.

Tool maintenance advice, repairs, and performance evaluations are part of the package. Allwell Cast understands that production downtime costs money, so issues are addressed quickly and professionally.

Even after years of use, clients can reach out for refurbishing services or mold upgrades. This long-term partnership approach builds trust and ensures the tooling remains a reliable part of the customer’s manufacturing system.

Conclusion

In summary, injection mold tooling by Allwell Cast delivers reliable results due to its precision, durability, and expert craftsmanship. Through high-quality materials, advanced manufacturing, and professional support, the company ensures consistent performance across every project.

Whether the goal is to produce millions of identical parts or to mold complex components with tight tolerances, Allwell Cast has the capabilities to deliver. Their reputation for excellence is not based on marketing—it is built on real outcomes. Manufacturers across the globe choose Allwell Cast because the tools work, last, and perform exactly as expected. That level of dependability is not easy to find, but at Allwell Cast, it’s part of every project.