ABOUT US

High precision components have been the most important contribution among various industries since day one.

As conditions continue to become more demanding, efficiency and accuracy become more crucial, and materials become even more premiums, we work alongside our customers to uncover every possibility.

As a precision metal fabricator, working with our customers, we help unleash potential.

Services and supports we are good at are as below:

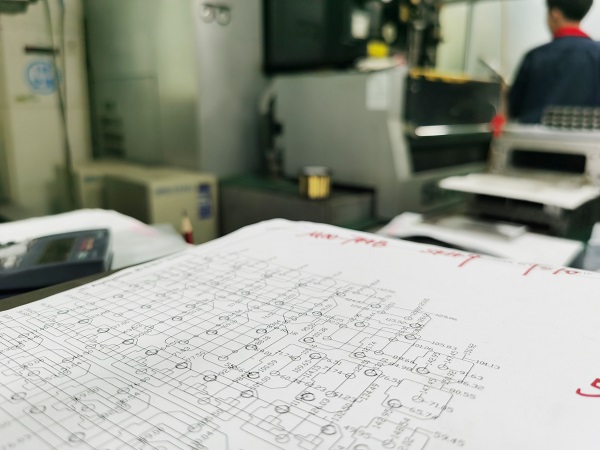

- Co-design,

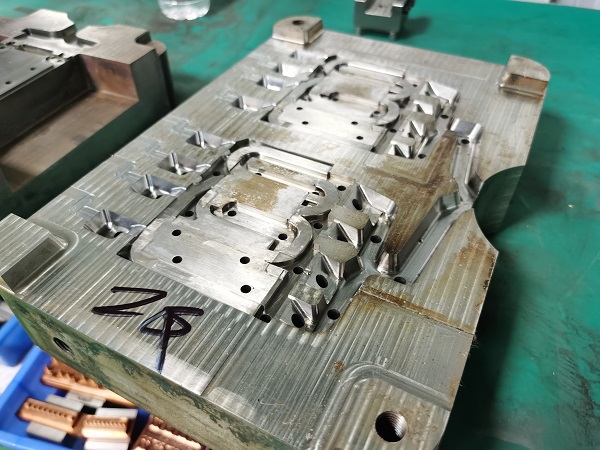

- Tool design and tool construction,

- Die-casting,

- Mechanical operations,

- Surface finishing,

- Assembling.

- Small volume of order(500pcs,)

- Free mold tool for volumn production

The materials we can handle are:

- ZAMAK,

- ALUMINUM,

- PLASTIC

- STAINLESS STEEL,

- IRON,

- and more to explore.

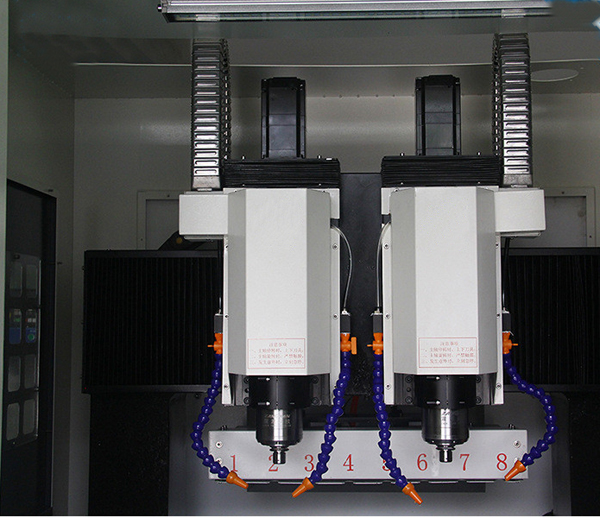

We have full set of die-casting machines, subsequent machining machines, and surface treatment facilities in house – prepared to be your step stone of your success!

With full metal fabrication facilities in house and all-in-one person contacting with you, it will save you a big money and make your work so much easier! Due to the uniqueness of each of these processes, as well as the diversity of the raw materials utilized, we fulfill exacting needs with solutions that maximize efficiency.

In addition to products, we also proudly offer to help optimize effectiveness. Like our all-in-one working way allowing customers to contact with only one representative from our company. You don’t have to worry to be flooded by emails from all various departments. You only need to communicate with one representative to work.

Our team has 2 decades of collective experience in helping people just like you improve production efficiency, accuracy, precision and component quality in all ways.

Helping customers from various industries, we have built a remarkable presence throughout the world. We want to do more than this and we want to help improve more industries.

- Machinery And Automation Industrialization

- 5G Telecom Infrastructure

- Solar Energy And PV High Precision

- Automotive Manufacturing

- 3C Consumer Electronics

- Apparel and Fashion

- Perfume Caps Luxury Use High Precision

- Building and Security Monitoring Components

- More to be explored……

From small Kate spade exquisite snap hook, I phone camera stand, Nvidia graphics processing unit frame, to motor shell of the PV engine, we are with you.

To us, this is more than a solution and fabrication. It is a passion. And we strive to be the most dependable, trouble-free part of your business process. We are ALL WELL PRECISION.

And together, we create certainty. We enable success. And we release innovation.

Custom Manufacturer of Architectural and Door Handles

Alongside their primary function, high-grade architectural hardware adds an aesthetic touch. We are a renowned custom door handle manufacturer, known for our meticulous handles and snap hooks for commercial buildings, used by architects and construction specialists.

Expertise in Manufacturing Custom Door Handles

With several years of experience in the production of architectural hardware, we offer custom door handles that are fit for the particulars of every assignment. From modern, minimalistic to classic, ornate looks, we guarantee exceptional durability, perfect surface finish, and comfortable functionality.

WHY US?

Money saver

From mold tooling, die casting, subsequent machining processing, surface treament, assembly, to packaging, the full facilities in house save you big money working with us.

Time saver

Only one English speaking representative to contact, no flooded emails from various departments.

Quality protector

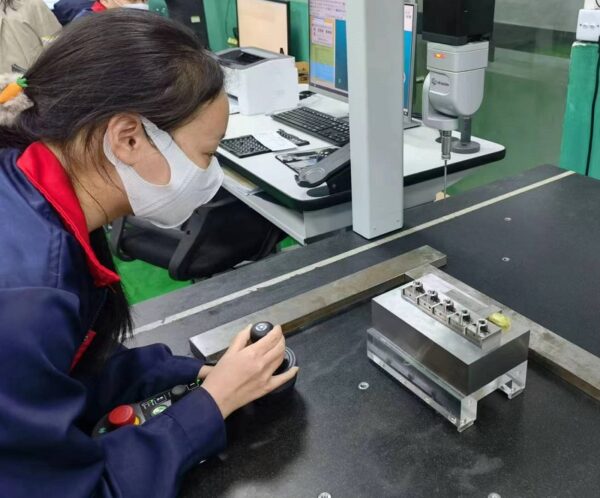

From cradle technical assessment, material verification, in-process quality control, to strick full dimensional checking, we think what you think to make sure high quality components delivered.

Value adder

Intensive communication makes sure immediate response, short lead time, and less cost to add value to your business.

End to end communication

only one English speaking engineer contact person for efficiency contact.

Simultaneous engineering service partner

providing cradle to grave program service to ensure the concept turn into reality cost effectively.

Program management

intensive communication makes sure immediate response, short lead time, and less cost.

State-of-the-art finishing quality

State-of-the-art finishing quality for beauty and accessories.

530 million

Components produced each year

250+

Employees

1998

More than 20 years of experience

2900

Tons of zinc alloy processed every year

Our Factory Pictures